Rizzing up the DECromancer MFM Emulator

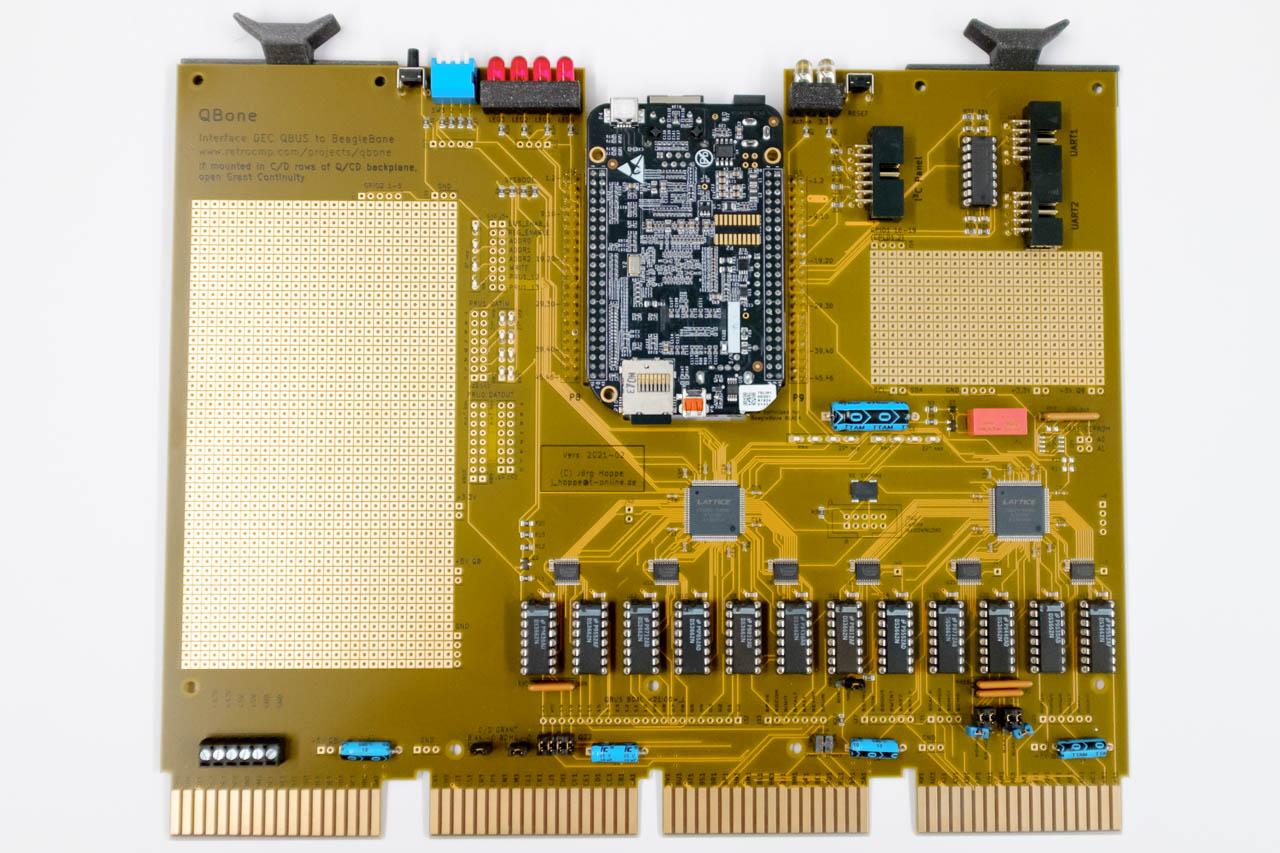

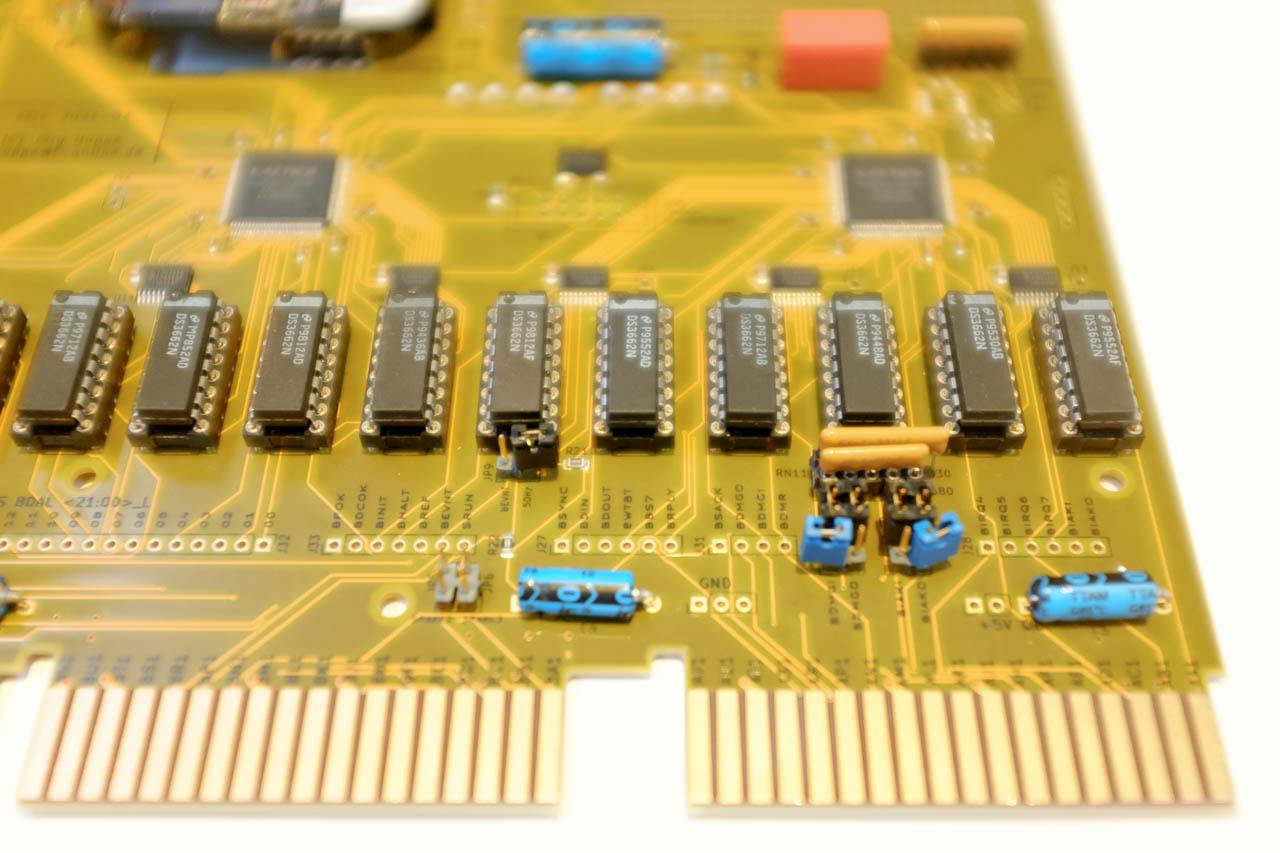

Our Revision D MFM Emulators come with an upgrade already present on our QBone boards: peripheral expansion connectors.

The tiny JST SH (1mm spacing) connector is compatible with all Qwiic and Stemma QT devices. With literally hundreds of devices out there, this is the fastest and cheapest way to add physical interfaces to the emulator.

We used a SparkFun Qwiic joystick and a SparkFun Qwiic Alphanumeric Display in purple for this little demo, written entirely in a short shell script. Press the button and the text MFME appears. Check the comments in the script for further details. It would not be difficult to mount the display and joystick as a way to display more information about the currently loaded image, or reconfigure options and start/stop/restart the emulator.

You can also use the 18-pin FPC flat-cable connector with most Adafruit "EYESPI" displays. However, you must use an A-A (top on both sides) cable. Do not use the Adafruit A-B cable (connectors "flipped" on opposite ends) when connecting displays. We have tested and recommend the GCT 05-18-A-0127-A-4-06-4-T 5 inch cable available for under CAD$2.

This demo video uses that cable and an Adafruit 2.8" TFT LCD with capacitive touch. It manages full-screen video playback, though it is running without emulation running at the same time. We don't expect you want to display full-screen video during emulation, but you should be able to provide a nice menu and touch-based interface for control and feedback if that strikes your fancy.

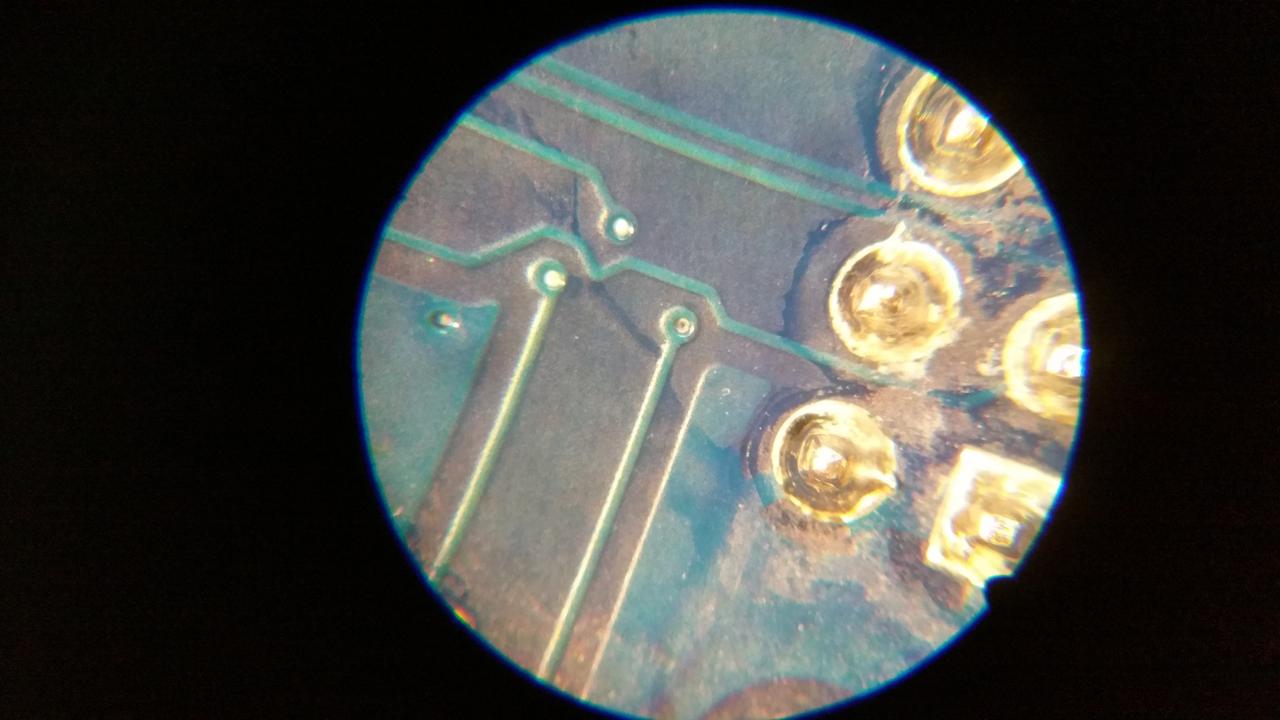

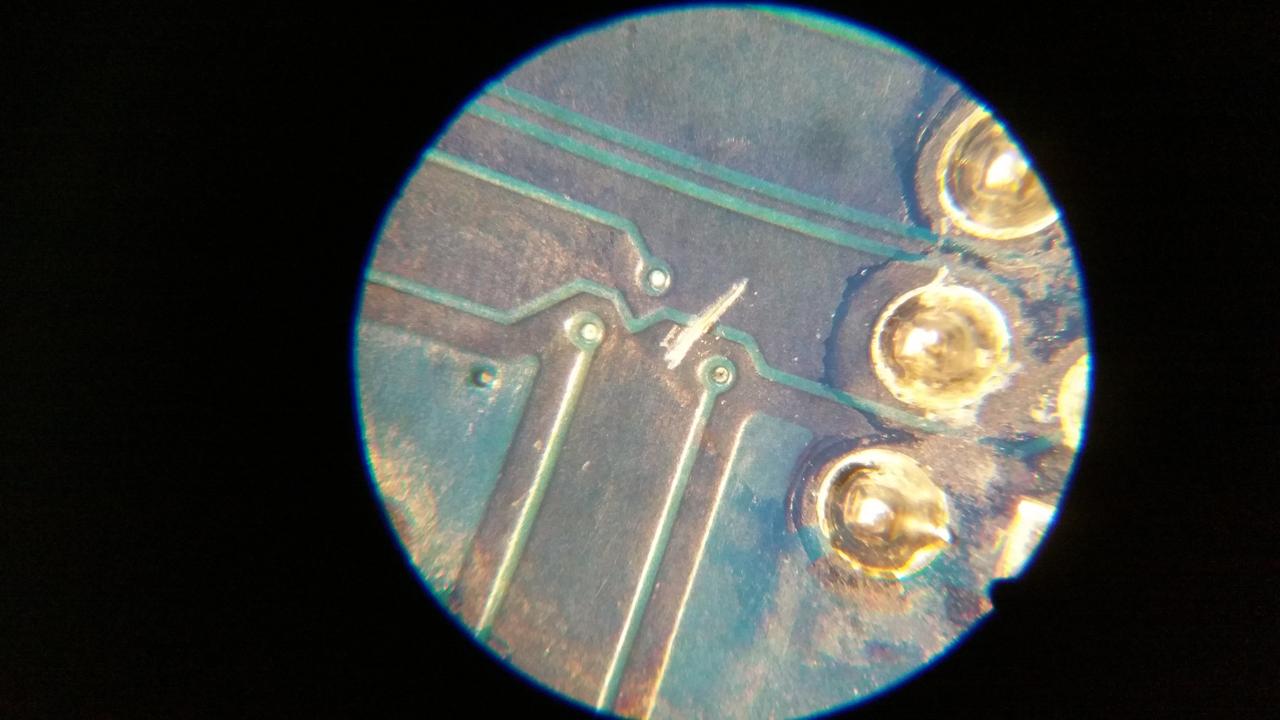

Please note that our earlier Rev D boards have an error in layout that requires cutting a trace. If your Rev D emulator has the 2D square barcode on the back, and a silkscreened serial number, you don't need this fix. Otherwise, cut the angled trace on the back side near the EYESPI connector to field-patch your MFM emulator:

The PCB is only two-layer, so don't worry about cutting through interior traces. There aren't any.

I have held back publishing this information for a while, but I shouldn't have. Sorry about that. There's simply not enough hours in the day for me to integrate this as fully as I'd like into emulation. Hopefully the information provided is enough for those of you in the community have more time. And who knows, maybe I'll find time over the winter holidays.